Cutting Costs and Boosting Efficiency: The Power of Six Sigma

Introduction

Escalating operational costs and shrinking profit margins force business leaders to find solutions that deliver measurable results. Six Sigma provides a systematic answer–a data-driven methodology that identifies waste, eliminates inefficiencies, and transforms underperforming processes into profit-generating assets.

This proven approach targets the root causes of costly defects, redundant workflows, and resource waste that silently drain your bottom line. Rather than implementing quick fixes, Six Sigma creates lasting improvements through structured analysis and measurable change.

You’ll discover exactly how professional Six Sigma services help businesses achieve significant cost reductions and efficiency gains across manufacturing, service, and technology sectors–giving you the practical insights needed to evaluate whether this methodology could transform your operations.

Main Takeaways

- Proven Waste Elimination: Six Sigma uses data-driven analysis to eliminate non-value activities, streamlining workflows and cutting material waste that drains your operational budget.

- Defect Prevention Saves Money: The DMAIC methodology tackles root causes of costly defects, reducing warranty claims and customer service expenses before they impact your bottom line.

- Enhanced Resource Efficiency: Strategic process improvements boost equipment utilization, inventory management, and workforce productivity across all business functions.

- Industry-Agnostic Results: Six Sigma delivers sustainable cost savings and operational excellence across manufacturing, healthcare, and financial services regardless of company size.

How Six Sigma Works to Improve Operations

Most business improvement efforts chase symptoms rather than tackle root causes. You’ve likely seen this pattern: quick fixes that work temporarily but problems resurface months later. Six Sigma transforms this reactive approach into a precision-driven system that consistently delivers measurable results through systematic operational excellence.

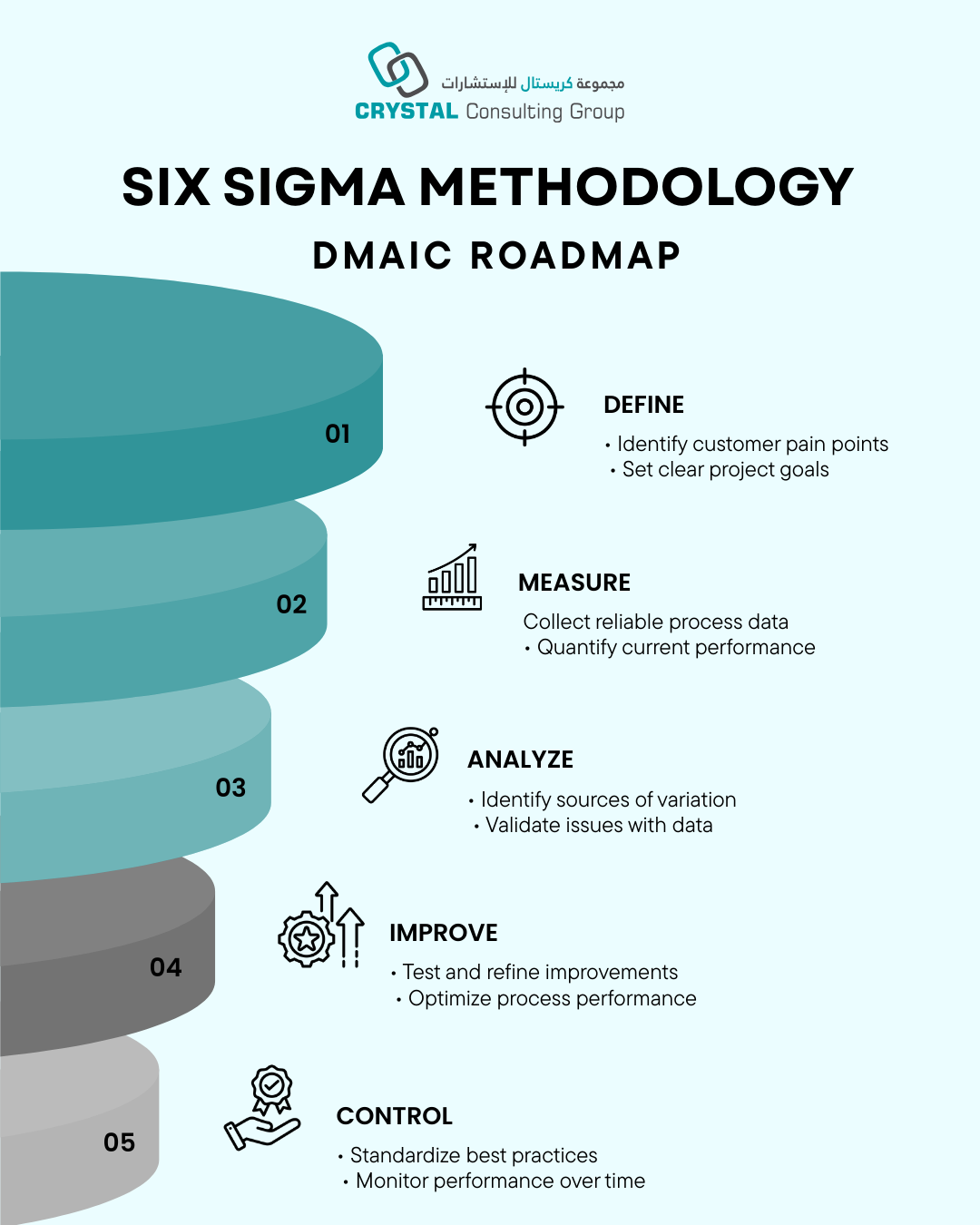

Six Sigma operates through the DMAIC methodology–a five-phase framework that guides your organization from problem identification to sustainable solutions. Define establishes clear project boundaries and goals, ensuring your team solves the right problems rather than treating symptoms. Measure creates baseline performance metrics through comprehensive data collection, often revealing surprising gaps between perceived and actual performance. Analyze uses statistical tools to identify root causes, digging deeper than surface-level observations to understand what truly drives inefficiencies.

The Improve phase develops targeted solutions based on analytical findings, testing changes on a small scale before full implementation. Finally, Control establishes monitoring systems and standard procedures to prevent performance regression, ensuring improvements stick over time rather than fading after initial enthusiasm wanes.

This methodology fundamentally shifts your organization’s decision-making from opinion-based to evidence-based processes. Data-driven decision-making leads to faster, more-informed decisions that generate stronger bottom lines, greater creativity and commercial success, and more engagement and collaboration from employees. Statistical analysis reveals patterns that casual observation misses, identifying inefficiencies that traditional management methods overlook entirely.

Standardizing processes across teams and departments reduces the variation that creates waste and unpredictable outcomes. When everyone follows proven procedures backed by data, your organization achieves consistent results while establishing a foundation for continuous improvement that compounds benefits over time. Process improvement provides a structured approach to overseeing and optimizing organizational workflows, eliminating inefficiencies, reducing costs and improving productivity.

While these benefits prove substantial, successful implementation requires careful planning and employee buy-in. The Atlantic notes that employees typically found Six Sigma’s implementation frustrating and confusing, and according to data from 2006, among the large companies that adopted the program, 91 percent wound up trailing the S&P 500 in stock performance. Despite these implementation challenges, the systematic approach to operational improvement creates the foundation for sustainable efficiency gains that extend far beyond initial deployment.

These operational improvements translate into measurable cost savings across key business areas. Let’s explore how Six Sigma reduces expenses in practical ways that impact your bottom line.

Key Ways Six Sigma Services Reduce Business Costs

Your business loses 20-30% of revenue through hidden inefficiencies–waste, defects, and poor resource allocation that traditional management misses. Six Sigma services expose these concealed expenses by applying systematic analysis to reveal exactly where your resources disappear and how to reclaim them.

This methodology transforms cost management from reactive firefighting into proactive optimization. Instead of waiting for problems to surface through complaints or budget overruns, Six Sigma identifies improvement opportunities through data analysis and process examination. This shift from treating symptoms to eliminating root causes creates sustainable cost reductions that compound over time.

Waste Elimination and Process Optimization

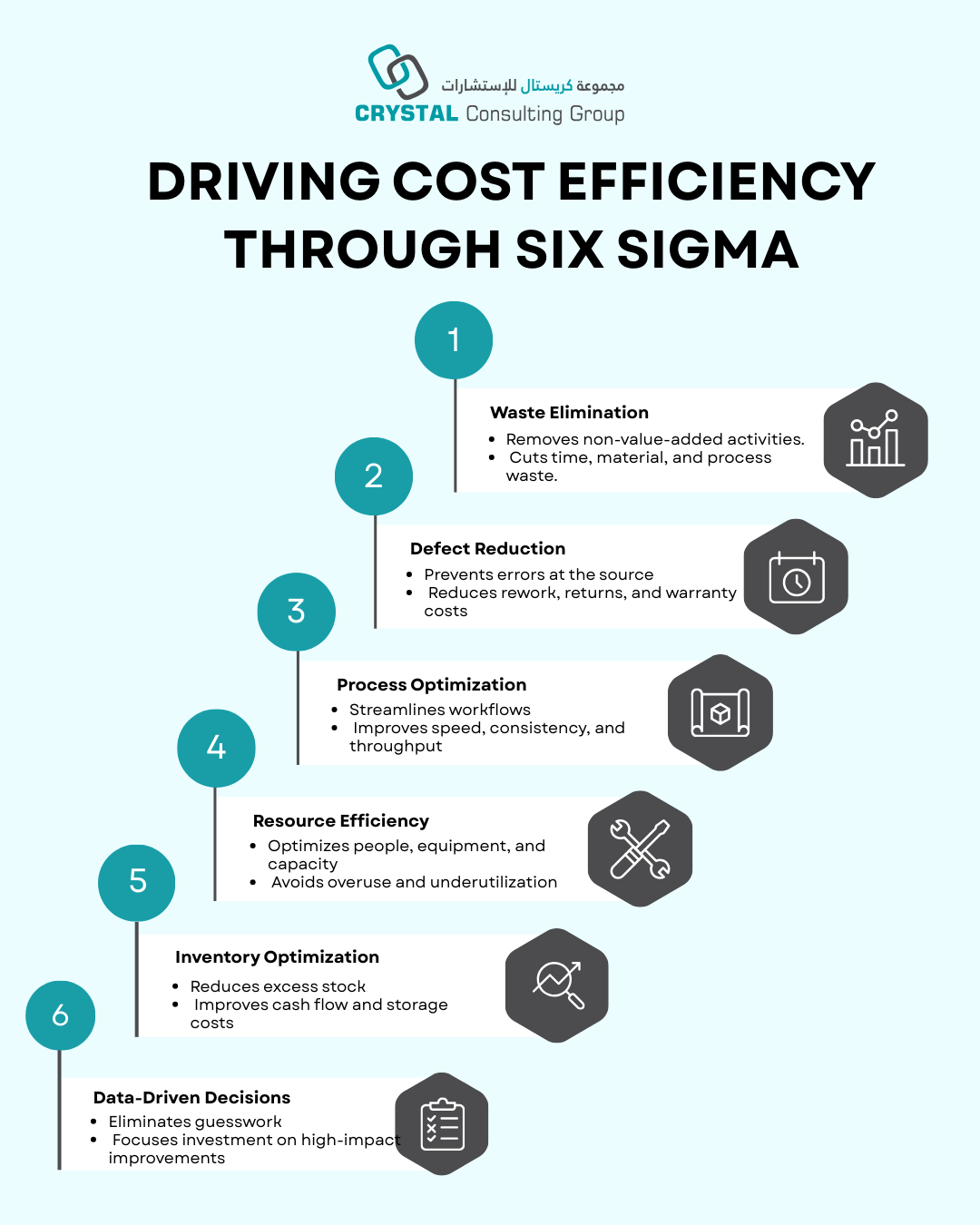

Every business operation contains activities that consume resources without adding customer value. Six Sigma services use value stream mapping to identify the eight types of waste: overproduction, waiting, transportation, inappropriate processing, unnecessary inventory, unnecessary motion, defects, and unused employee creativity. Professional consultants systematically examine your workflows to reveal inefficiencies that internal teams often miss due to familiarity with existing processes.

Process improvement redesigns workflows to eliminate bottlenecks and redundancies while maintaining quality standards. The methodology creates smooth, continuous flow that minimizes handoffs and delays between process steps. You’ll often discover that significant portions of your activities add no customer value, creating immediate opportunities for cost reduction through elimination or consolidation.

Defect Reduction and Quality Improvement

Poor quality creates cascading costs that extend far beyond immediate rework expenses. Customer returns, warranty claims, inspection activities, and service complaints all represent preventable expenses that Six Sigma services address through robust error-prevention systems. Statistical process control tools monitor quality metrics in real-time, preventing defects before they occur rather than catching them after production.

Enhanced quality improvement initiatives reduce the need for extensive quality control resources, allowing you to reallocate staff and equipment to value-added activities. When defect rates decrease consistently, you can reduce inspection frequencies and quality control overhead while maintaining customer satisfaction levels.

Resource Allocation Optimization

Six Sigma services analyze resource utilization patterns to identify opportunities for improved allocation across staff, equipment, and facilities. Capacity planning becomes more accurate when you understand true demand patterns and process capabilities through statistical analysis. This insight helps prevent both overcapacity waste and under-capacity bottlenecks that drain profitability.

Research shows that 29 percent of organizations reported more than 20 percent savings from process optimization initiatives. Operational efficiency requires businesses to refine processes, reduce waste, and improve resource management to achieve the best output with the least input.

Inventory management improvements represent particularly significant cost reduction opportunities. Six Sigma tools help you balance carrying costs with service levels, reducing excess inventory while maintaining customer satisfaction. Better demand forecasting and supplier performance management contribute to lower total inventory costs while improving cash flow.

These systematic improvements create lasting financial impact that extends well beyond initial implementation, establishing capabilities for ongoing operational optimization. With these cost reduction mechanisms in place, let’s examine which industries can maximize these benefits most effectively.

Industries That Benefit Most from Six Sigma Services

Manufacturing, healthcare, and financial services consistently achieve exceptional Six Sigma results because their operations generate the measurable data and process complexity that make this methodology most effective. While Six Sigma can improve operations across any sector, certain industries possess the ideal conditions for statistical analysis and process optimization that create dramatic transformations.

Manufacturing organizations achieve the strongest Six Sigma results because their operations create abundant measurable data. Production environments generate clear metrics around defect rates, cycle times, and equipment efficiency that translate directly into cost savings. These companies often discover immediate opportunities to reduce material waste, optimize production schedules, and improve quality management system implementations. The structured approach proves particularly valuable for manufacturers dealing with complex supply chains, multiple production lines, or stringent quality requirements where small improvements create substantial financial impact.

These opportunities expand when manufacturers integrate lean manufacturing principles with Six Sigma to create comprehensive improvement programs. This combination addresses both systematic defects and operational waste, creating powerful synergies that maximize efficiency gains. Companies implementing both approaches typically see faster results because lean principles help eliminate obvious waste while Six Sigma tackles more complex quality issues.

Healthcare organizations increasingly turn to Six Sigma services to address rising operational costs while improving patient outcomes. The methodology’s focus on error reduction proves essential in environments where mistakes carry significant consequences for patient safety. Process improvements in patient flow, medication management, and administrative workflows directly translate to reduced wait times, fewer medical errors, and streamlined billing procedures. Hospitals and clinics find that Six Sigma helps them standardize care protocols while eliminating inefficiencies that frustrate both patients and staff.

Banks, insurance companies, and investment firms benefit from Six Sigma’s ability to standardize complex processes and reduce processing times. These organizations typically manage high-volume, detail-oriented operations where small inefficiencies compound into significant costs. Six Sigma services help financial institutions streamline loan approvals, claims processing, and customer onboarding procedures while reducing errors that lead to compliance issues or customer dissatisfaction. Financial organizations that establish comprehensive quality management frameworks find they can better coordinate improvement initiatives across different departments, ensuring consistent implementation and sustained results.

Technology companies apply Six Sigma principles to software development cycles, customer support processes, and product deployment procedures. The methodology helps reduce bug rates, improve system reliability, and enhance user experience through systematic problem-solving approaches that complement agile development practices.

These industries see exceptional returns because Six Sigma services target the specific inefficiencies that matter most to their operations. Manufacturing’s production optimization opportunities, healthcare’s patient safety requirements, and financial services’ process standardization needs all align perfectly with the methodology’s data-driven approach, creating sustainable improvements that compound over time.

Transform Your Operations with Crystal Consulting Group’s Six Sigma Excellence

Six Sigma delivers powerful results—but only when executed with precision, experience, and cultural alignment. Crystal Consulting Group helps organizations translate Six Sigma principles into measurable cost savings, operational efficiency, and long-term competitive advantage.

Our certified experts bring deep industry insight and a practical, data-driven approach to eliminate waste, reduce defects, and embed continuous improvement into your organization’s DNA. We don’t just implement projects—we build capabilities that sustain performance gains long after engagement ends.

Your competitors are already optimizing their operations. With Crystal Consulting Group, you don’t just catch up—you lead. Now is the time to move beyond incremental change and achieve breakthrough results with Six Sigma done right.